Aluminum Marine Plate 5083-H321

Aluminum Marine Plate

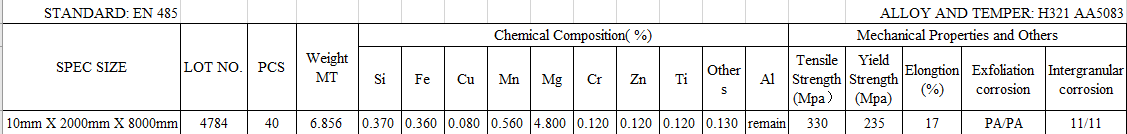

Alloy & Temper: 5083-H321

Standard: EN 485/573, ASTM B209, AMS 4027, AMS-QQ-A250, GB T3880, AA 35.1/2

Thickness: 3~200mm

Regular Width:1000/1020/1250/1270/1500/1520, 36.5", 48'5", 60.5", 72.5", Max width: 2600mm

Minimum Order Quantity(MOQ):7 tons per size

Alloy & Temper: 5083-H321

Standard: EN 485/573, ASTM B209, AMS 4027, AMS-QQ-A250, GB T3880, AA 35.1/2

Thickness: 3~200mm

Regular Width:1000/1020/1250/1270/1500/1520, 36.5", 48'5", 60.5", 72.5", Max width: 2600mm

Minimum Order Quantity(MOQ):7 tons per size

Next:

Aluminum Plate